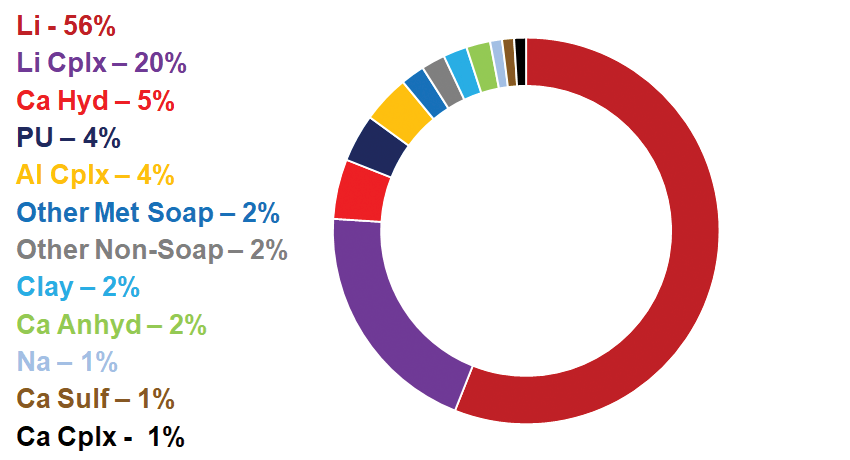

Grease thickeners play a crucial role in defining the properties and performance of the grease. They can be categorized into three main types: simple soaps, non-soap thickeners, and complex thickeners. Each type has distinct characteristics that make them suitable for various applications.

Simple Soaps

Simple soaps are the most basic type of grease thickeners, typically made from metallic salts of fatty acids. They tend to break down at higher temperatures and are less shear stable compared to complex soaps.

Examples:

- Lithium Stearate

- Lithium 12-hydroxystearate

- Calcium anhydrous

- Calcium hydrated (cup grease)

- Aluminum

- Barium

- Sodium

Pros:

- Cost-Effective: Generally less expensive to produce than complex thickeners.

- Good Lubricity: Provides adequate lubrication for many standard applications.

- Wide Availability: Easy to find and widely used in various industries.

Cons:

- Lower Thermal Stability: Breaks down at higher temperatures.

- Less Shear Stability: More prone to mechanical degradation under high shear conditions.

- Water Washout: Some simple soaps, particularly sodium, are less resistant to water washout.

Non-Soap Thickeners

Non-soap thickeners are made from materials other than metallic soaps. They offer unique properties, making them suitable for specialized applications.

Examples:

- Calcium Sulfonate: Good mechanical stability and water resistance.

- Polyurea: Known for good oxidative stability and suitable for sealed-for-life applications.

- Clay: Excellent for very high-temperature applications with no dropping point.

Pros:

- High-Temperature Stability: Particularly true for clay-based thickeners.

- Excellent Water Resistance: Especially in the case of calcium sulfonate.

- Long Service Life: Polyurea greases are ideal for applications requiring long-term lubrication without maintenance.

Cons:

- Cost: Typically more expensive than simple soaps.

- Complex Manufacturing: Requires more sophisticated production processes.

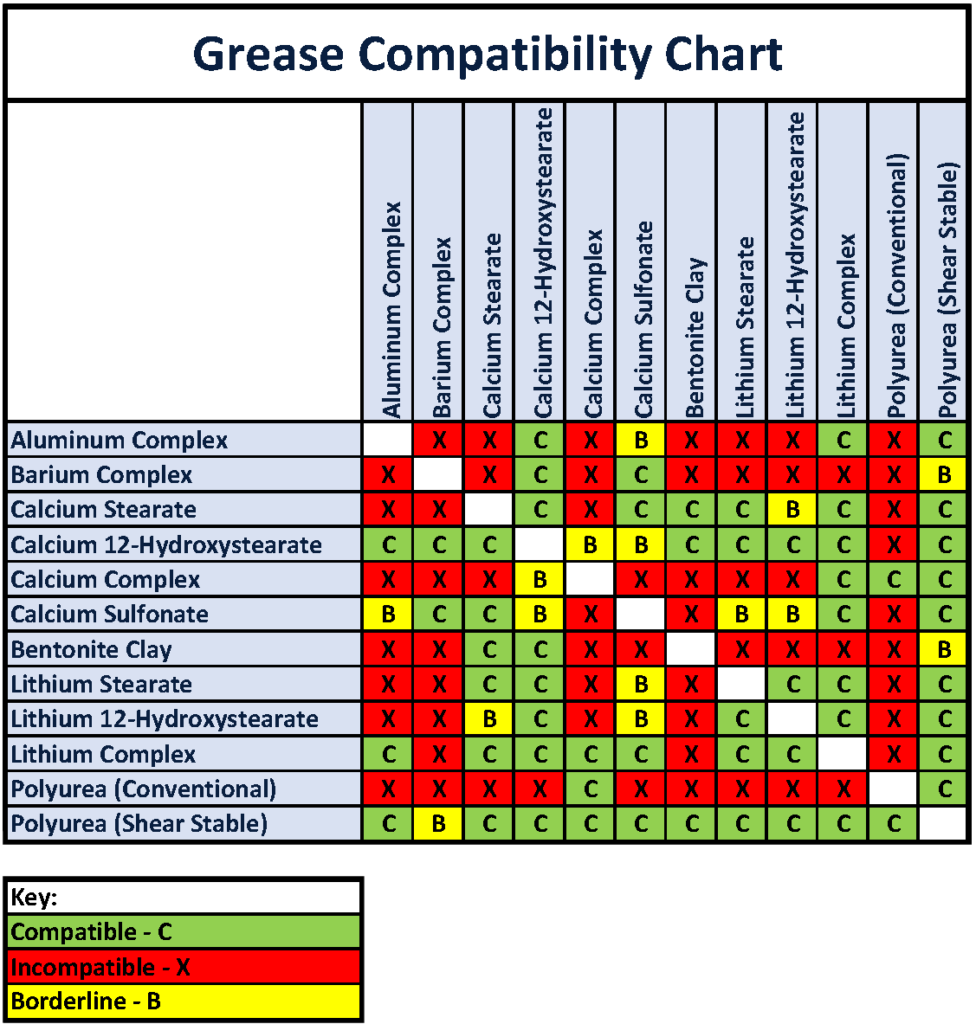

- Compatibility Issues: May not be compatible with all grease types or machinery components.

Complex Thickeners

Complex thickeners are created by adding complexing agents to simple soap thickeners, enhancing their performance and stability.

Examples:

- Lithium Complex: Offers high-temperature stability and mechanical stability.

- Aluminum Complex: Provides good water resistance and high-temperature performance.

- Calcium Complex: Known for improved water resistance and thermal stability.

Pros:

- High Shear Stability: More resistant to mechanical breakdown.

- Thermal Stability: Can withstand higher temperatures without degrading.

- Versatile: Suitable for a wide range of demanding applications.

Cons:

- Cost: More expensive to produce than simple soap thickeners.

- Complex Formulation: More intricate production processes required.

- Potential Additive Interference: Complex formulations may interact differently with various additives, requiring careful selection.

Understanding these categories and their respective pros and cons will help you to better select the most appropriate grease for specific applications, ensuring optimal performance and longevity of machinery components.

Unsure if accurate?