FUNCTIONS OF GREASE

FUNCTIONS OF GREASE

- Lubricant – Grease reduces friction between moving parts, ensuring smooth operation and preventing direct metal-to-metal contact.

- Prevent Wear – By forming a protective layer, grease minimizes surface wear and extends the lifespan of machinery components.

- Sealant – Grease acts as a barrier, preventing the ingress of contaminants such as dust and water into critical machine areas.

- Minimize Leakage – Its thick consistency helps to keep lubricants in place, reducing the likelihood of leaks from joints and seals.

- Oxidation Inhibition – Grease contains additives that prevent the oxidative breakdown of both the grease and the surfaces it lubricates, thereby extending the service life.

- Protect Elastomer – Grease helps to preserve elastomeric seals and gaskets by providing a protective coating that prevents drying, cracking, and other forms of degradation.

- Noise & Vibration Reduction – By dampening vibrations and filling gaps between components, grease helps to reduce operational noise and vibration.

- Rust & Corrosion Protection – The protective film of grease shields metal surfaces from moisture and corrosive substances, preventing rust and corrosion.

- Low Maintenance – Grease’s ability to stay in place and provide long-lasting lubrication means less frequent reapplication and maintenance, improving efficiency and reducing downtime.

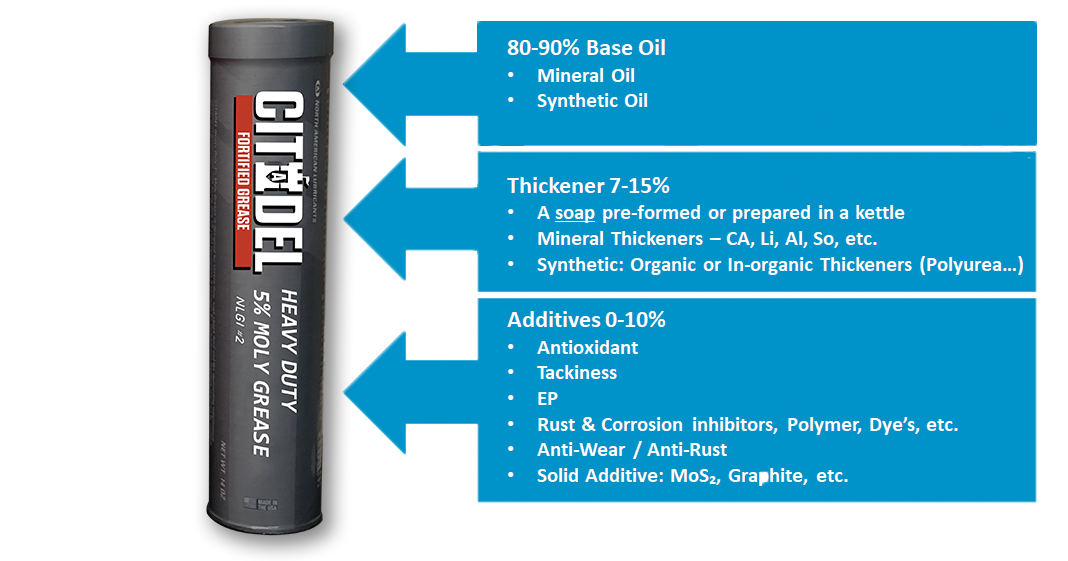

GREASE COMPOSITION

Base Oil – base oil is the primary fluid component in grease, serving as the foundation that determines many of the grease’s performance characteristics. Its quality and type significantly influence the grease’s overall performance, including its ability to reduce friction, protect against wear, and operate effectively under various conditions.

- Mineral

- Synthetic

- Natural

- Combined

Thickener – A thickener is used in grease formulation to give the grease its semi-solid structure and consistency. It works by forming a network within the base oil, trapping the oil and transforming it into a stable, gel-like substance. Thickener choice affects the grease’s properties, including its temperature tolerance, water resistance, mechanical stability, and compatibility with different materials.

- Soap or Non-Soap

Additives – additives in grease formulation are specialized chemicals incorporated into the base oil and thickener to enhance or impart specific performance characteristics. By tailoring the types and amounts of additives, grease manufacturers can create products that meet the specific demands of various applications and operating conditions.

Soluble Additives – additives that break down in water

- EP/AW

- Corrosion Inhibitor

- Antioxidants

- Polymers

Solid Additives – additives that stay solid in the presence of liquids

- Molybdenum

- Teflon

- Ca-Carbonate

- Graphite