Base Oils

Base oils are a fundamental component of lubricants, serving as the primary fluid in the formulation. They are responsible for providing lubricating properties to reduce friction and wear between moving surfaces. Base oils can be derived from various sources, and their characteristics play a crucial role in determining the overall performance of the lubricant.

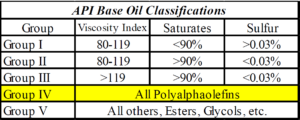

API Classifications

Base oils are classified into different groups based on their chemical composition and refining methods. The American Petroleum Institute (API) has organized base oil types into 5 groups dependent on their composition and characteristics.

Group I

Group I are mineral oils that are refined from crude oil. Group I base oils are the least refined and generally have a low viscosity index.

Group II

Group II are mineral oils that are refined from crude oil. Group II base oils are more refined and have a higher viscosity index. This provides improved oxidation stability, performance and thermal resistance.

Group III

Group III base oils are made using a more complex process and have an even higher viscosity index. Group III’s are more refined and produce an even higher quality oil with excellent oxidation stability, low-temperature properties and performance characteristics. Group III base oils are considered to be synthetic.

Group IV

Group IV base oils are known as polyalphaolefins (PAO). These fully synthetic base oils are chemically engineered to provide excellent performance characteristics, including: an ability to maintain viscosity over a wider temperature range, improved thermal stability, oxidation resistance, and low-temp fluidity.

Group V

Group V base oils encompass all oils that don’t fit into the other categories. Many Group V products are synthetic and can include additional oils used as additives to increase performance. Group V base oils are used in highly specialized applications that require specific properties.

Additives

Additives are compounds that are formulated to customize the performance and properties of lubricants for specific applications. Additives generally make up between 0-30% of a lubricant, depending on its application. Additives can be broken down into 3 basic categories: additives that protect against oxidation, additives that add to or improve the properties of the base oil or additives that protect metal surfaces.

-

Anti-Wear Additives:

These additives form a protective film on metal surfaces, reducing friction and preventing wear and damage to the equipment. They are used in engine oils, compressor oils, hydraulic oils, greases, transmission fluids and many industrial lubricants.

-

Antioxidants:

Antioxidants prevent the lubricant from forming carbon-based acids, which are corrosive to metal surfaces. They reduce the formation of varnish, gums, asphaltenes and sludge. They are used in just about every type of automotive or industrial lubricant or grease.

-

Detergents:

These additives clean and protect metal surfaces. They help prevent harmful surface deposits and neutralize acid contaminants. They are used in engine oils, hydraulic oils, transmission fluids, metalworking fluids and greases.

-

Demulsifiers:

Demulsifiers improve base oil properties by maintaining proper viscosity and protecting metal from the corrosive effects of water. They are used in gear oils and industrial lubricants.

-

Emulsifiers:

Emulsifiers allow liquids that are not normally soluble to mix together, such as oil and water. They are typically used in soluble oil metalworking fluids.

-

Dispersants:

Dispersants also help protect metal surfaces. They keep soot and insoluble contaminants in stable suspension and prevent the formation of deposits, sludge and varnish. They are used in engine oils, transmission and hydraulic fluids, ear oils and industrial lubricants.

-

Anti-Foam Agents:

These additives reduce or eliminate the formation of foam, which can lead to poor lubrication and reduced efficiency. They provide stable oil film and cooler operating temperatures. They are used in hydraulic fluids, engine oils, transmission fluids, gear oils and industrial lubricants.

-

Viscosity Modifiers

These additives help control the viscosity, or thickness, of the lubricant under different operating conditions, ensuring it maintains its lubricating properties at both low and high temperatures. They improve base oil properties, which is desirable for a multi-grade lubricant.

-

Friction Modifiers:

These additives reduce friction between moving parts, reducing the amount of energy needed and increasing efficiency.

-

Rust and Corrosion Inhibitors:

These additives protect metal surfaces from rust and corrosion caused by moisture and other contaminants. They are used in engine oils, transmission and hydraulic fluids, gear oils, grease, fuel improvers and industrial lubricants.

-

Extreme Pressure Additives:

These additives are used in applications where high pressures and loads are present, such as in gearboxes. They provide additional protection by forming a lubricating film under extreme pressure conditions. They are used in gear oils, greases and many industrial lubricants.

-

Tackiness Agents:

These additives promote adhesion of lubricant to the metal surface and promote cohesion within the lubricant. They are used in grease, gear oils and industrial lubricants.

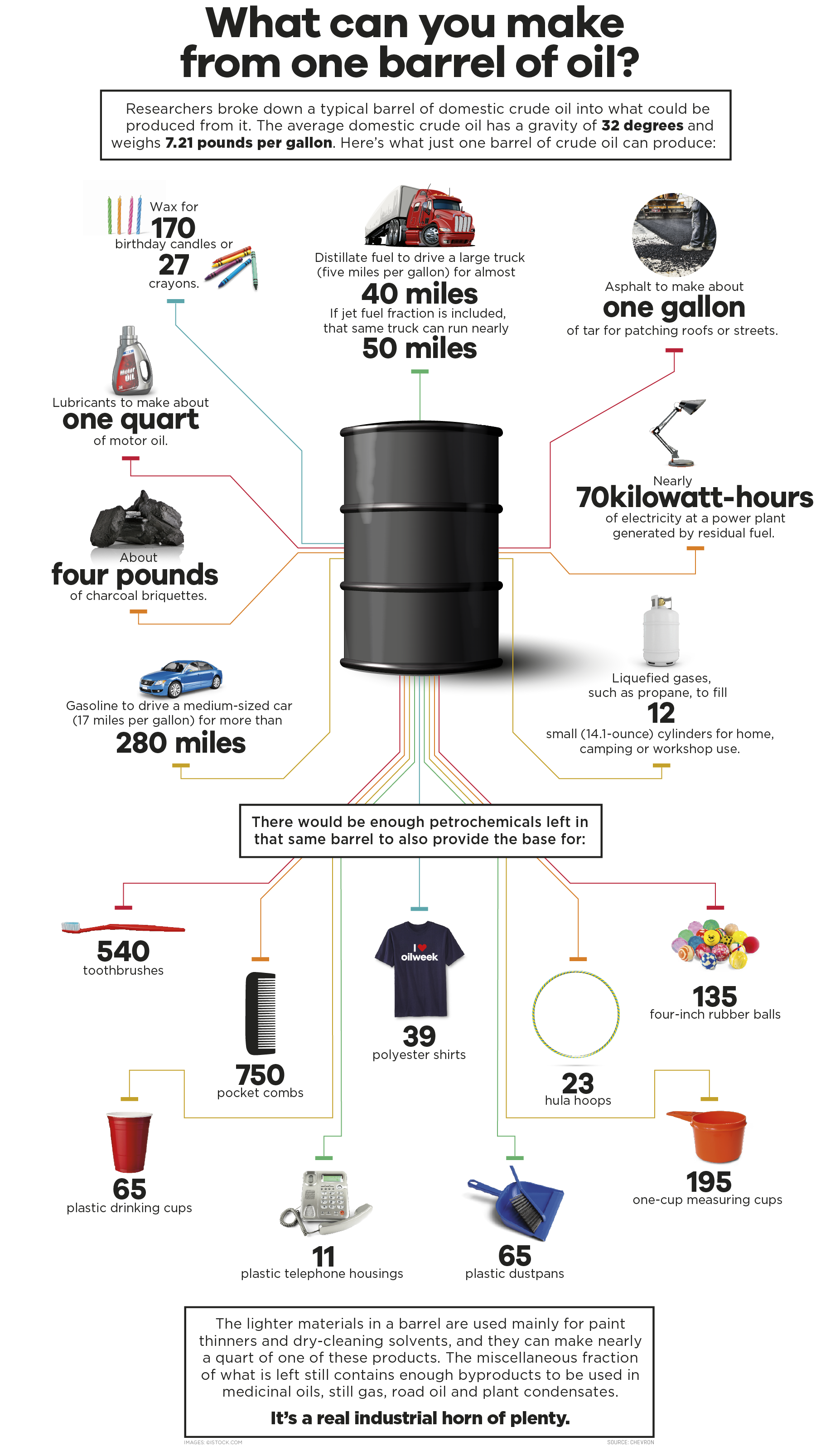

Refining Process

-

Atmospheric Distillation

- Used to separate fuel from the crude oil, the products are known as distillates.

-

Vacuum Distillation

- Used to distill and separate heavier elements that would be damaged during atmospheric distillation. This process is used to obtain the base oil viscosity and flash point, it also provides the four distillates that finished petroleum products are made from.

-

Refining

- This process removes unwanted chemicals from the base oil to improve its characteristics. There are two main types of refining:

- Solvent Extraction: this method extracts any undesirable components from the distillates via a liquid extraction. After solvent extraction, the leftover materials are de-waxed and hydrofinished to improve their color and stability.

- Catalytic Hydrogenation/Hydrotreating: this subjects distillates to a chemical reaction with hydrogen in the presence of a catalyst. This reaction takes place at extremely high temperatures and pressure. This is the favored method of many modern refineries because of the superior quality of the produced base oil and lack of waste.

- This process removes unwanted chemicals from the base oil to improve its characteristics. There are two main types of refining:

-

De-asphalting

- This step removes any heavy asphalt residue that may impact a distillates quality.

-

De-waxing

- This step is performed to reduce the wax content of a base oil to further improve its low-temperature properties.

A pared down version of the refining process is as follows:

Blending

- Although blending is not technically a step in the refining process, it is the final step in creating a finished lubricant. By blending different base oils and additives to obtain specified viscosity and properties you create different types of lubricants.